You might be searching for data and information related to gas flushing, or you might even be interested in the whole idea of how it works. Similarly, you might even be asking yourself if it’s your right packaging application for your food. Most likely, you might as well be one of the locally established food packaging companies, and you are looking into ways of venturing into the food distribution business. Don’t panic; you are at the right place.

When you come across the term gas flushing, it merely refers to the entire process mostly used in food packaging types, going by modified atmosphere packaging. The process alters the package inside via a unique kind of pouch used in packaging specific types of foods.

Recently, modified atmosphere food packaging is gaining attraction when it comes to food preservation. One of the reasons this method is getting so much attention is its ability to maintain food quality and freshness for quite a period.

The probability is that you are probably researching this new method of food preservation known as gas flushing, and that’s why you ended up finding yourself here. The whole idea of packaging some food items can be nerve breaking, especially when this food is sensitive to packaging materials and methods. Gas Flushing pouches might probably be the method you are searching for.

What is Gas Flushing?

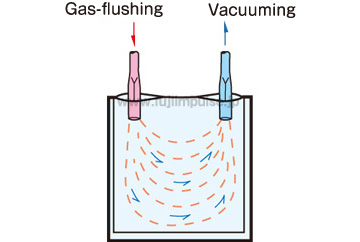

Gas flushing can get defined as when different inert gases, preferably nitrogen, get injected inside, then get sucked out and re-injected back again in a repetitive manner and removed all the oxygen in the food. This method is one of the most types of atmosphere packaging that improves the packaged food items’ shelf life.

What is Modified Atmosphere packaging?

Modified Atmosphere packaging refers to the standard practice for causing the atmosphere to change inside the packaged food is contained. This method gets precisely preferred for food items such as fish, beef, and pork. The whole idea of adopting this packaging method is to increase the lifespan of these highly perishable goods.

Other food items such as poultry, cheese, and some fish types get packaged using a different kind of packaging known as MAP applications. MAP application uses the same process as the gas flushing.

Reasons why one should use gas flushing

Modified gas atmosphere packaging reduces the oxygen levels by approximately 97 percent, and in some instances, the percentage can even be less. The whole gas flushing process works under a fundamental physics principle. The inert gases used are denser than oxygen, and due to this fact, the oxygen contained in the packaging item gets flushed out. The other denser gases get flushed into the package.

Gas flushing comes with some benefits that users can redeem by using this method. One of these methods is enhancing the food items’ shelf life. Secondly, the technique protects foods against food discoloring through an added layer of protection in the package. In essence, the inert gasses in gas flushing are buffer to the packaged product.

When deciding on which type of gas flushing method to adopt, it is essential to consider that various gas flushing methods get designed for specific food types. Different food types require a different gas combination to perform their function effectively. For example, certain meat types need carbon dioxide or monoxide and nitrogen mixture to formulate the flushing gas. Nitrogen is mostly the gas that gets used to cover and surround the item packaged.